Surface Mount Devices (SMD) are at the heart of modern electronics, enabling compact, efficient, and high-performance designs. The SMD package type refers to the physical form and footprint of electronic components that are mounted directly onto a Printed Circuit Board (PCB) surface, eliminating the need for wire leads through holes. This blog dives into the details of various SMD package types, their applications, advantages, and challenges.

What are SMD Packages?

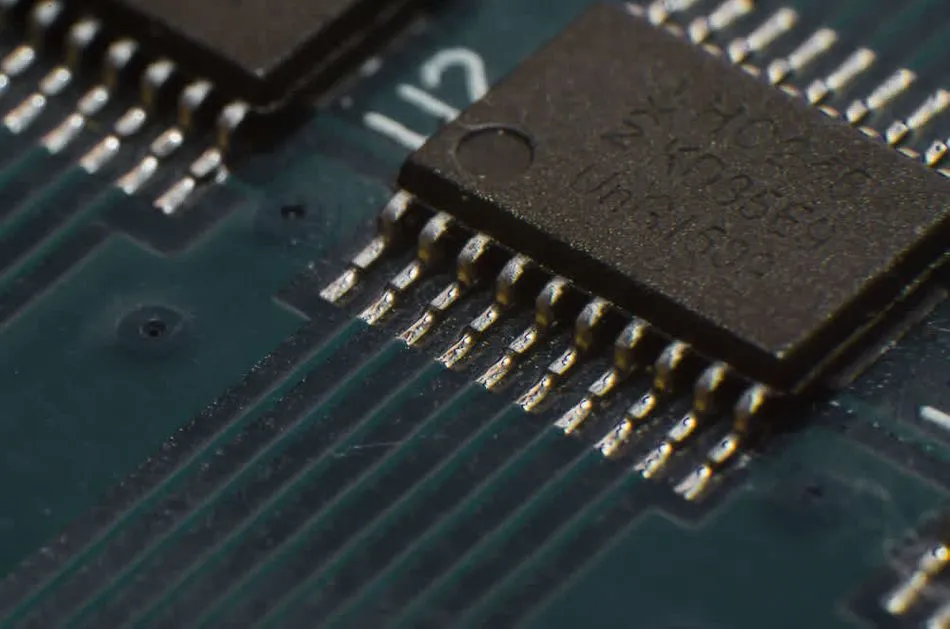

SMD packages are enclosures for electronic components designed to be soldered directly onto a PCB surface using Surface Mount Technology (SMT). Unlike traditional through-hole components, SMDs allow for denser circuit designs, making them ideal for modern electronic devices like smartphones, laptops, and IoT devices.

SMD packages can house a wide range of components, including resistors, capacitors, diodes, transistors, and integrated circuits (ICs). The choice of package type depends on factors such as thermal performance, electrical requirements, mechanical stability, and available space.

Common SMD Package Types

1. Passive Component Packages

Passive components such as resistors, capacitors, and inductors come in standardized SMD packages.

- Chip Packages:

- Sizes: 0402, 0603, 0805, 1206 (dimensions in inches, e.g., 0402 is 0.04” x 0.02”).

- Applications: Widely used for resistors and capacitors in compact electronics.

- Advantages: Small size, high reliability, and easy integration in automated assembly lines.

- MELF (Metal Electrode Leadless Face):

- Features: Cylindrical shape with metalized ends.

- Applications: High-reliability environments such as automotive electronics.

- Challenges: Harder to handle during assembly compared to flat chip packages.

2. Transistor and Diode Packages

SMD packages for transistors and diodes are designed to handle varying power levels and electrical specifications.

- SOT (Small Outline Transistor):

- Types: SOT-23, SOT-89, SOT-223.

- Applications: Amplifiers, switching circuits, voltage regulators.

- Advantages: Compact size, low parasitic capacitance, and inductance.

- DO (Diode Outline):

- Examples: DO-214 (for diodes like Schottky and Zener).

- Applications: Power supply protection, signal rectification.

- Advantages: High reliability and easy placement on PCBs.

3. Integrated Circuit (IC) Packages

ICs are available in a wide variety of SMD packages, each designed for specific applications.

- SOIC (Small Outline Integrated Circuit):

- Features: Dual in-line layout with pins on the side.

- Applications: Logic ICs, memory chips, analog circuits.

- Advantages: Smaller than DIP (Dual In-line Package) while offering high pin density.

- TSSOP (Thin Shrink Small Outline Package):

- Features: Ultra-thin design with high pin counts.

- Applications: Microcontrollers, ADCs, DACs.

- Advantages: Suitable for compact, high-density designs.

- QFP (Quad Flat Package):

- Features: Pins on all four sides, typically used for large ICs.

- Applications: Microprocessors, FPGAs, DSPs.

- Advantages: High pin count, good heat dissipation.

- Variants: TQFP (Thin QFP), LQFP (Low-profile QFP).

- BGA (Ball Grid Array):

- Features: Pads arranged in a grid underneath the package, connected via solder balls.

- Applications: High-performance processors, GPUs, memory modules.

- Advantages: Excellent thermal and electrical performance, compact size.

- Challenges: Requires precise assembly and inspection techniques like X-ray imaging.

4. LED and Optoelectronic Packages

SMD packages for LEDs and optoelectronic components are optimized for light emission and sensitivity.

- PLCC (Plastic Leaded Chip Carrier):

- Applications: LEDs in displays and indicators.

- Advantages: High brightness, durable plastic enclosure.

- COB (Chip on Board):

- Applications: High-power LEDs in lighting applications.

- Advantages: Superior thermal management and high lumen output.

5. Power Packages

Power components require SMD packages that can handle high currents and dissipate heat effectively.

- DPAK and D2PAK:

- Applications: Power transistors, MOSFETs, voltage regulators.

- Advantages: High thermal dissipation and mechanical stability.

- TO (Transistor Outline):

- Examples: TO-252, TO-263.

- Applications: Power amplifiers, high-current circuits.

- Advantages: Designed for high power dissipation with heat sinks.

Advantages of SMD Packages

- Space Efficiency:

- SMD packages are much smaller than their through-hole counterparts, allowing for high-density circuit designs.

- Automated Assembly:

- SMT is compatible with automated pick-and-place machines, increasing manufacturing efficiency.

- Improved Performance:

- Lower parasitic inductance and capacitance ensure better performance at high frequencies.

- Cost-Effective:

- Reduced material usage and efficient manufacturing processes lower overall costs.

Challenges of SMD Packages

- Assembly Complexity:

- Requires advanced soldering techniques like reflow soldering.

- Inspection of solder joints can be challenging, especially for BGA and other hidden-pad packages.

- Thermal Management:

- Smaller package sizes can lead to thermal issues, requiring effective heat dissipation solutions.

- Repair and Rework:

- SMD components are harder to handle manually during repairs compared to through-hole components.

- Moisture Sensitivity:

- Certain SMD packages are prone to moisture ingress, requiring proper storage and handling.

Choosing the Right SMD Package

When selecting an SMD package, consider the following factors:

- Electrical Requirements: Voltage, current, and frequency ratings.

- Thermal Performance: Heat dissipation needs and PCB thermal design.

- Mechanical Constraints: Available PCB space and assembly tolerances.

- Cost and Availability: Ensure the package is within budget and readily available.

Future Trends in SMD Packaging

- Miniaturization:

- As devices become smaller, SMD packages continue to shrink, enabling ultra-compact designs.

- Advanced Materials:

- Use of new materials for improved thermal and electrical performance.

- Integration:

- Multi-chip modules (MCM) and System-in-Package (SiP) solutions are gaining popularity for integrating multiple functions into a single package.

- Environmental Sustainability:

- Lead-free and halogen-free SMD packages are becoming standard due to environmental regulations.

Conclusion

SMD package types play a crucial role in modern electronics, offering diverse solutions for a wide range of applications. Understanding the nuances of each package type helps engineers make informed decisions during design and manufacturing. As technology evolves, SMD packaging will continue to push the boundaries of what’s possible in electronic design. Whether you’re a student, hobbyist, or professional engineer, mastering SMD packages is an essential step toward creating cutting-edge electronics.